https://www.worknc.com/

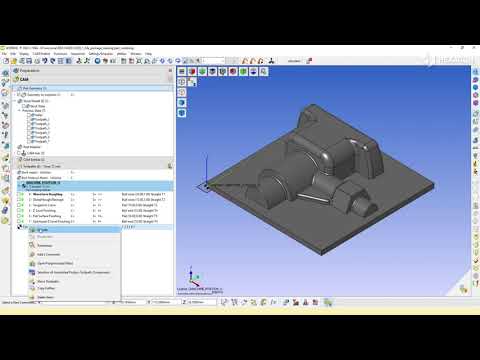

Advanced Toolform Roughing Benefits | WORKNC 2020.1

WORKNC 2020.1’s Roughing with Advanced Toolform technology allows the milling process to deliver a more accurate roughing stock, eliminating imprecisions characteristic to the traditional parametric toolpath calculation.

https://www.worknc.com/

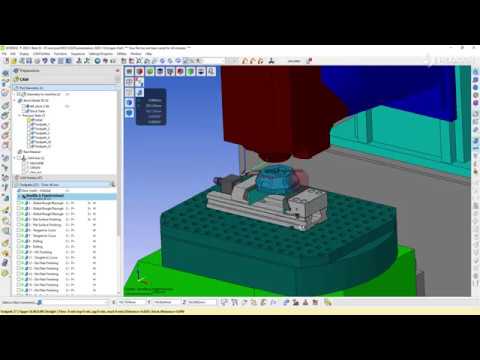

NCSIMUL Export | WORKNC 2020.1

Manufacturing data created in WORKNC is brought automatically into NCSIMUL, including fixtures, roughed stock, design part, program origins, machine programs, and complete cutting tool library.

From the WORKNC to NCSIMUL link interface, users can elect the Digital Twin Machine available to prove out post-processed G-code programs. This seamless process can transfer multiple part set-ups for verifying multiple operation G-code.

https://www.worknc.com/

WORKNC | Designer Workzone Creation | WORKNC 2020.1

WORKNC | Designer brings an enhanced link to WORKNC, now preparing the entire workzone before sending it to the manufacturing planning phase of the process.

https://www.worknc.com/